Embracing the Future of Manufacturing: B-Tec Solutions’ Journey with Exotic Metals and Additive Manufacturing

July 3rd, 2024Embracing the Future of Manufacturing: B-Tec Solutions’ Journey with Exotic Metals and Additive Manufacturing

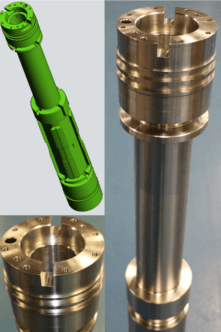

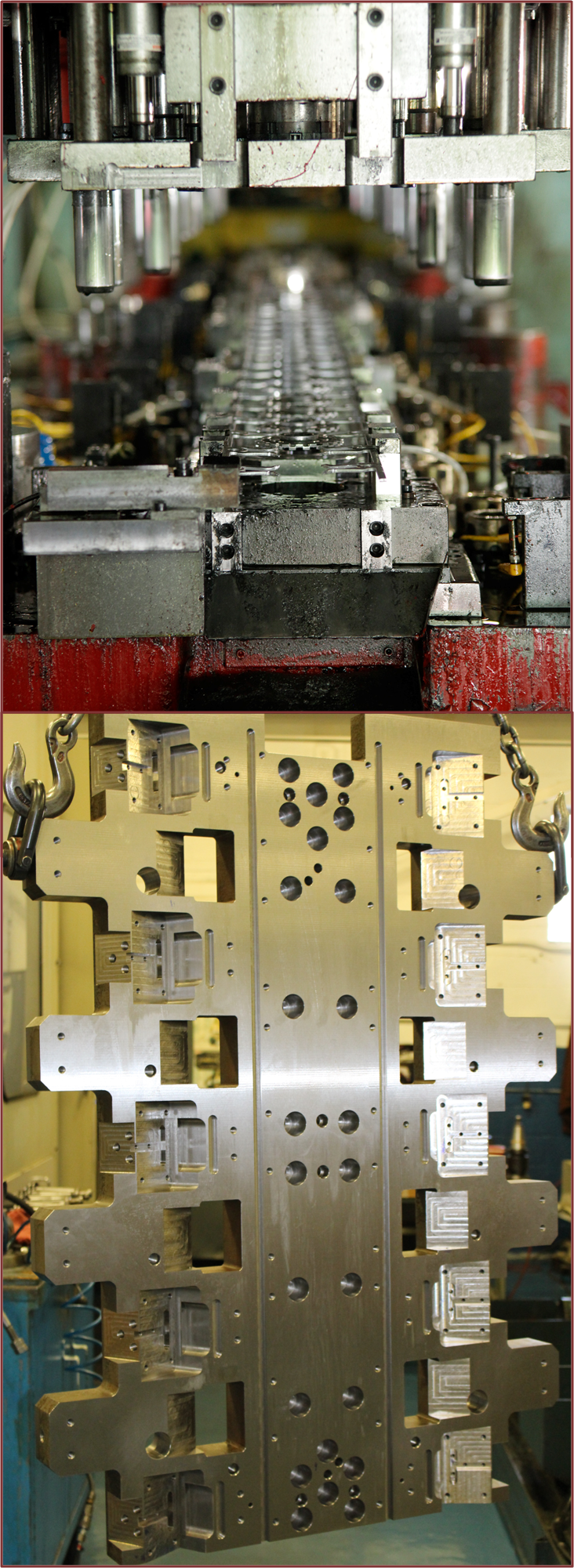

In the realm of modern manufacturing, precision, innovation, and the ability to work with exotic materials are defining factors for success. B-Tec Solutions stands at the forefront of this dynamic industry, specializing in a diverse array of materials such as Stainless Steel, Titanium, Inconel, Beryllium Copper, Cobalt Chrome and STEILITE 21. With a comprehensive suite of services including subtractive machining, advanced 3D additive printing, and stamping, B-Tec Solutions has carved out a niche as a leader in high-performance metal manufacturing.

Pioneering Additive Manufacturing

One of the standout features of B-Tec Solutions is its commitment to additive manufacturing (AM). For the past Six years, the company has steadily advanced in this field, beginning with their first Renishaw AM400 single-laser additive metal printer and recently upgrading to the new Renishaw AM500 quad-laser system. This progression underscores their belief that additive manufacturing represents the future of the industry, offering substantial reductions in both cost and lead time while maintaining uncompromising quality standards.

Meeting Complex Demands

B-Tec Solutions caters to a clientele with exacting requirements. Their typical customers demand parts made from challenging materials, precise tolerances, and rigorous quality documentation. Holding the ISO 9001:2015 certification is a testament to B-Tec Solutions’ commitment to consistently delivering high-quality products that meet global standards.

Infrastructure and Expertise

Spanning an impressive 85,000 square feet of shop floor space and supported by a dedicated team of approximately 100 skilled professionals, B-Tec Solutions possesses the infrastructure and expertise necessary to tackle projects of varying scales and complexities. Their capabilities range from crafting single parts for Mars rovers to producing low-volume components for human-rated reusable rocket engines, as well as manufacturing millions of safety-critical parts for automotive applications.

Embracing Innovation and Collaboration

At the heart of B-Tec Solutions’

Read More