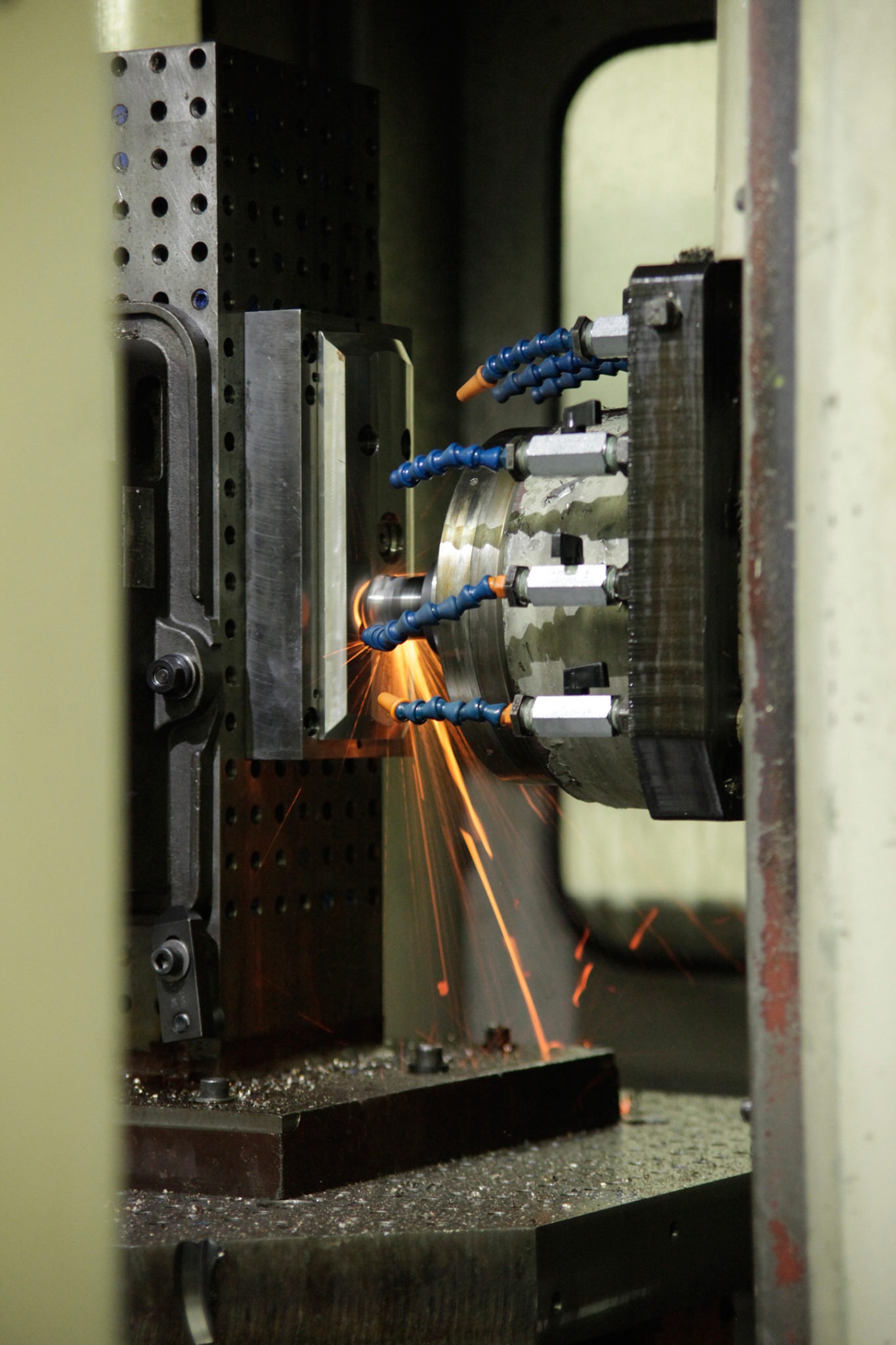

CNC Machining

Btec will translate your design as a direct input into our CNC (Computer Numerical Control) machines using the latest in CAM software, enabling our Team to produce the part configuration you need using the materials you specify within the tolerances you require.

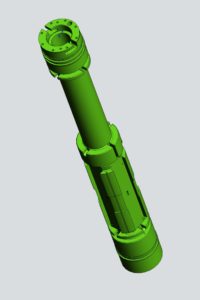

We do not do your average machining. Our equipment and staff work on specialized and unique projects that cannot be done at your typical shop. Our Aerospace, Automotive and Energy customers need uncommon and high specificity products made through complex design and manufacturing.

Btec specializes in finding the best methods to produce your CNC machining parts in materials such as– Inconel, Titanium, Hastelloy, Waspaloy, and Cobalt, as well as other common materials such as Stainless steel, Aluminum, Copper, and a variety of Castings.

From start to finish our team will manufacture your item and your specific needs in the CNC process. Our portfolio is diverse with transportation, aerospace, heavy industrial products and more, so our versatility and history of creating great products are what has kept customers coming back to us. Our Supply Chain Management will procure the material and components to meet your specifications. Next, our use of cutting tool technology and the latest in CNC equipment ensures that our methods will yield the most accurate and cost-effective process to meet your needs. After the items have been produced our Quality Assurance team will test and make sure that all the tensions required for your product meet our high standards.

Btec’s plant is full of equipment that we will use to create your final CNC machined product:

- 11 Horizontal Machining Centers; Size 60in x 80in

- 4 & 5 Axis

- 11 Vertical Machining Centers; Size 60in x 80in

- 13 CNC Lathes, Size 32in OD x 80in Length

- 6 New CNC Machines Added

- 2 Okuma Lathes

- 2 Okuma 3 Axis Mills

- 2 Okuma 4 Axis Mills