Stamping

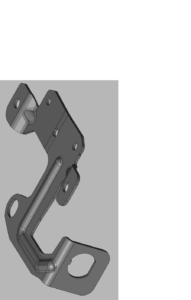

Stamping is a process of placing a flat sheet of metal in either blank or coil form into a stamping press where a tool and die forms the metal into a specific shape. Btec’s staff uses its expertise in the stamping process which necessitates a keen eye with the utmost precision and expertise. Metalworking has provided solutions for countless generations and has been utilized by a majority of industries due to its nature of being cost-effective and the mass-production capabilities it brings to the manufacturing table.

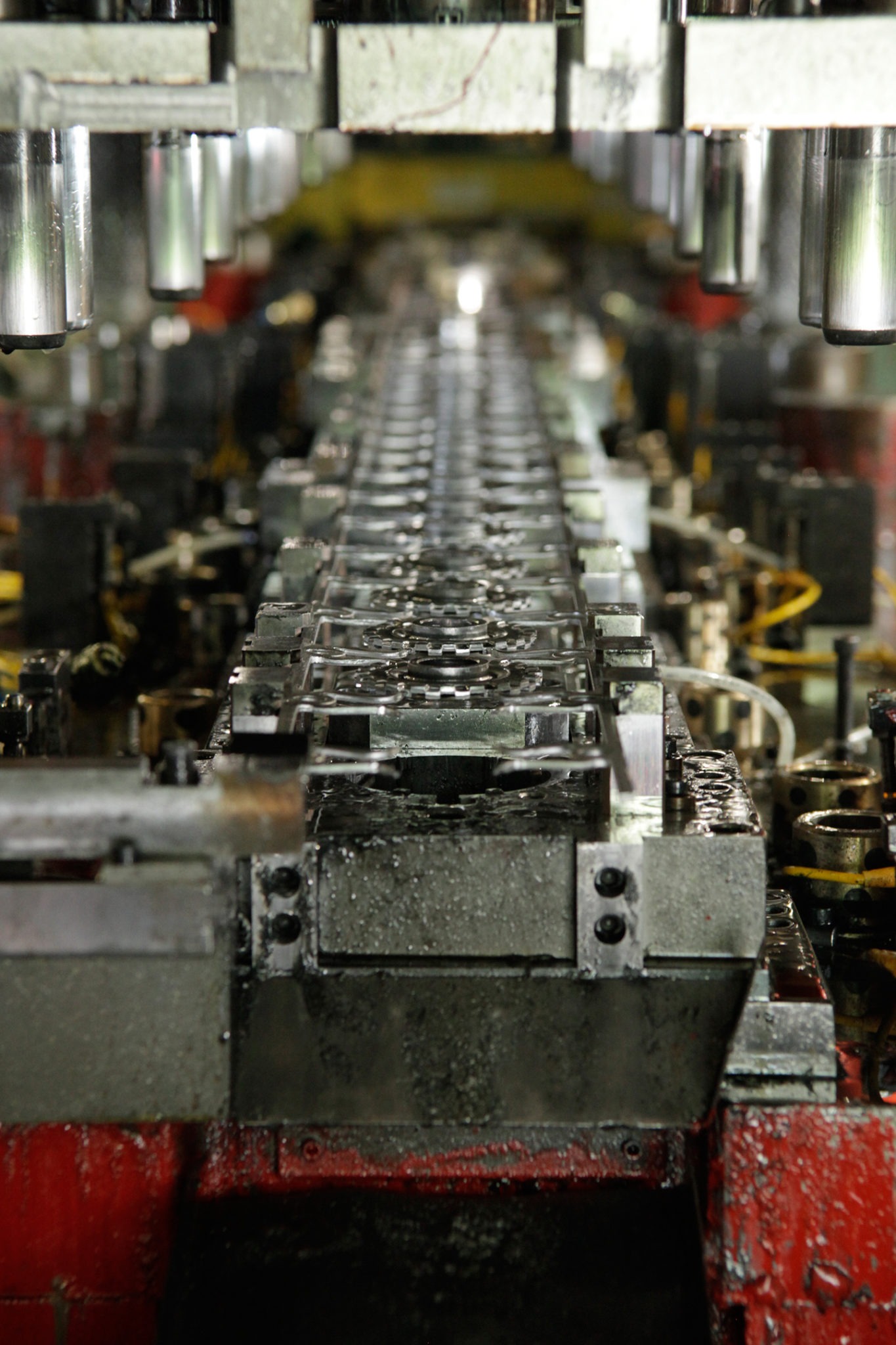

Btec utilizes 11 stamping presses that range from 45 to 1000 Tons for stamping operations in our plant. Both hydraulic and mechanical presses are utilized by our team.

Btec’s presses are up to date with the latest controls, safety equipment, and servo feeders which provide our customers with efficient, safe and cost-effective stamping services. Our largest press, a 1974 Pacific Hydraulic Press was recently overhauled in 2016 and rebuilt by our tremendous staff. A new power unit, new electronics, hydraulics, and motor, among other components, were replaced and has the hydraulic press running like new. Because of the hard work we put into maintaining and the expertise we have with our machinery, we can offer short run and high volume production processes to meet your manufacturing needs.

Our team has the unique position of understanding multiple layers of the complex precision metal manufacturing world. Btec’s ability to design, build and manufacture your tool or die all in-house makes the workflow process smooth since we have the full range of metal manufacturing knowledge and an abundance of machinery which provides flexibility to our offerings. In addition, with Btec’s compliment of both skills and equipment, we can complete your stamped product with secondary operations such as welding, assembly, plating and other processes. Please see the Tool & Die Services page for additional information and details.