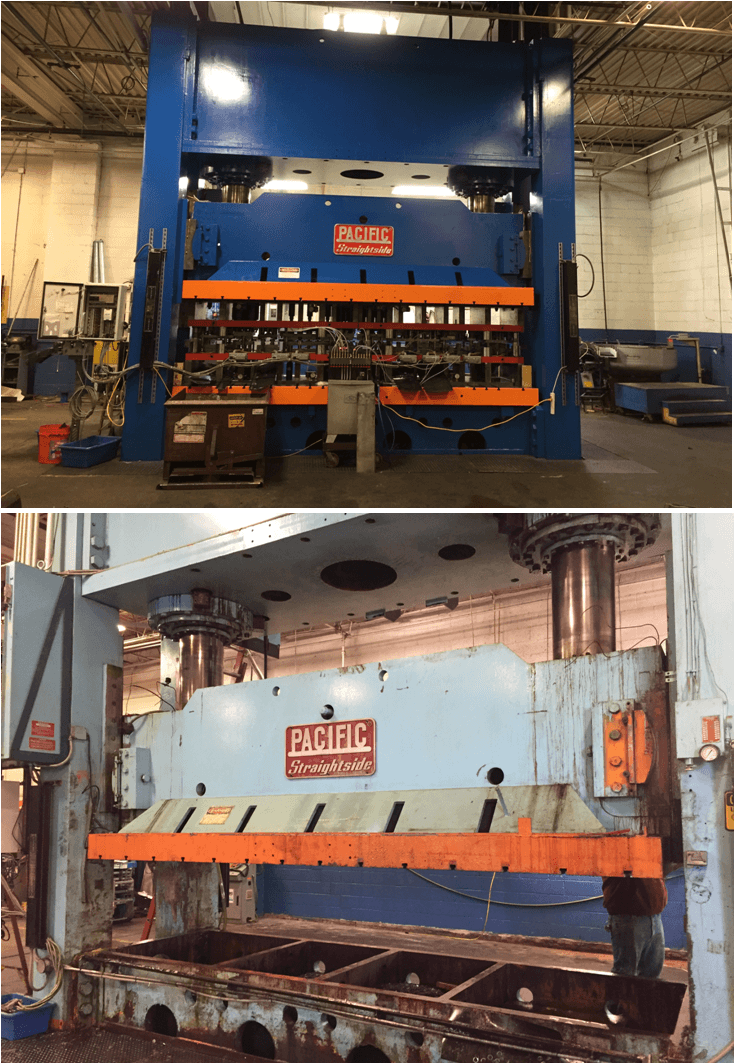

The 1974 Pacific Hydraulic Press has the capability of up to 1,000 tons of force and stamping ability. The press was last rebuilt in 1998 and had many hours of use since Btec purchased the behemoth of a machine in 2003. This press has been used for specific automotive customer projects, and with the reoccurring demand for higher quantities year after year, it was time to make a big change in the 1974 model. We wanted a press with more power, and we wanted to make it work like new. So we rebuilt it.

The original manufacturer, Pacific Press, supported the effort from the beginning. From the beginning it was asked, how do we make this 40-year-old machine not only run like new but run better than new, with all the latest technology? The Team decided to rip apart the machine and bring it down to its shell. A new power unit, new electronics, new hydraulics, a new motor… they scrapped what was old and rebuild the press with new and customized parts to make this press be the best it has ever been.

Some of the advantages to the new press include:

- The Rapid Speed of the press is now doubled compared to what it was just two months ago.

- The motor has been increased to 200HP and includes a soft start option to ease demand on the electrical system.

- All new hydraulic pumps were added to move the over 1,300 gallons of hydraulic fluid through the system.

- New precision scales to monitor slide movement and accuracy.

Our customers demand high-level products that are safety critical and need to be produced on-time. Our team took the time to completely rebuild this machine from the ground up and gave it a new life.

The rebuild of this 1000 ton stamping machine puts Btec in a position to produce many millions of pieces over the next decade. The newly revamped machine will be fully supported by our in-house team of Tool Engineers and Tool Makers.

To learn more about the Stamping, Custom Die, and Manufacturing work that Btec can do for you, please fill out the form below.