A Guide for 5 axis CNC Novices

Not all manufacturing is the same. Not all techniques, tools and CNC machines are alike either. There are various components that need to be made for customers, from Aerospace components to Energy, to Automotive to Consumer products and much more. All of these industries need specifying sizes, cuts, angles, and borrows made by EDM (Electrical Discharge Machining) or CNC (Computer Numerical Control) machining techniques. Staying up to date with machinery updates and technologies and understanding their benefits is a “no brainer” in custom metal machining. This is why 5 axis machining has added great versatility to Btec’s shop floor while adding to the robust equipment that we use when we work on precision metal manufacturing projects for our customers.

What is 5 axis machining?

5 axis machining is a highly progressive way to machine metals. A 5 axis machine refers to the 5 directions that a cutting tool can create while programmed. Not only can these machines cut in 5 directions, but they can work with tough metals which make a 5 axis a popular and specialized machining technique coveted by Industrial and Aerospace customers, that use titanium, cobalt, hastelloy, waspaloy, and inconel. The precise programming and cutting abilities of a 5 axis help to reduce turn-around time on a traditional project by being able to machine the item from different sides and angles without having to reposition the metal.

How does 5 axis machining work?

CNC machines stand for Computer Numerical Control, which refers to a programmer encoding a plan of action into a machine for cutting of metals to a specific roughing, shape and size. There are axes or direction that a cutting tool, base, and machine can move.

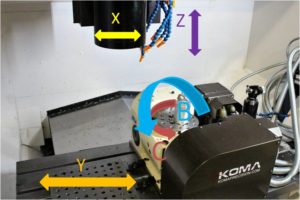

The 5 axes are the B, C, X, Y and Z axis — B axis is the base of the area where a metal material is fixtured and set in the machine. This can move from 30-110 degrees. The C axis rotates the B axis in clockwise or counterclockwise directions. The X axis is the base OR the spindle with the cutting tool moving left and right. The Y axis is the base moving forward and back. And finally, the Z axis is an up and down movement of the tool spindle. See diagram below for reference.

5 axis Okuma CNC machine diagram to explain the 5 movements of the machining process

The world of metal manufacturing is technical, robust and ever-changing. Btec has learned to embrace the newest technologies and machines to create a large skill set and equipment list of 3 axis, 4 axis and 5 axis machines to cover all of our bases, while proudly embracing the title of an AS9100 certified company.